Control valves used for water coils are typically: – Control valves are critical components in water coil systems, responsible for regulating fluid flow and temperature. This comprehensive guide explores the types, sizing, selection, actuators, installation, maintenance, and applications of control valves used for water coils, providing a thorough understanding of their role in efficient and effective HVAC systems.

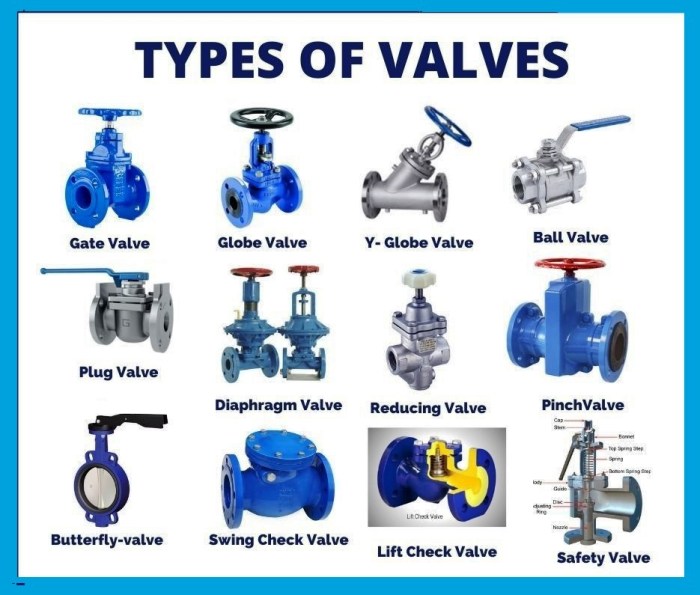

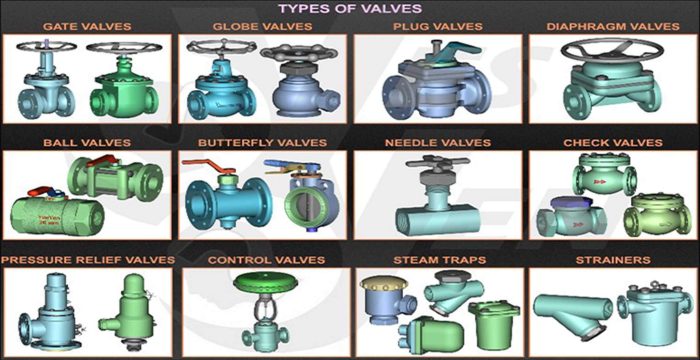

The diverse types of control valves, including globe valves, butterfly valves, and ball valves, each serve specific purposes and applications. Valve sizing and selection are crucial to ensure optimal system performance, considering factors like flow rate, pressure drop, and valve capacity.

Control Valves for Water Coils: Control Valves Used For Water Coils Are Typically:

Control valves play a crucial role in regulating the flow of water in water coils, ensuring optimal performance and efficiency in various HVAC systems.

Types of Control Valves

There are several types of control valves used for water coils, each with its unique characteristics and applications:

- Globe Valves:These valves have a spherical plug that moves linearly within the valve body, providing precise flow control.

- Butterfly Valves:These valves feature a circular disc that rotates within the valve body, offering low resistance to flow.

- Ball Valves:These valves have a ball-shaped plug with a hole through it, which rotates to control flow.

- Gate Valves:These valves have a rectangular gate that slides up and down to control flow, providing a full-bore opening.

Valve Sizing and Selection

Proper sizing and selection of control valves are essential for efficient water coil operation:

- Flow Rate:Determine the required flow rate through the valve based on the water coil’s capacity.

- Pressure Drop:Calculate the pressure drop across the valve to ensure it does not exceed the system’s capabilities.

- Valve Capacity:Select a valve with a capacity that meets or exceeds the required flow rate and pressure drop.

Valve Actuators

Control valves are operated using various types of actuators:

- Electric Actuators:These actuators use electric signals to control the valve’s position.

- Pneumatic Actuators:These actuators use compressed air to operate the valve.

- Hydraulic Actuators:These actuators use hydraulic fluid to operate the valve.

Valve Installation and Maintenance, Control valves used for water coils are typically:

Proper installation and maintenance are crucial for reliable control valve performance:

- Installation:Ensure the valve is installed in the correct orientation and securely fastened.

- Maintenance:Regularly inspect and clean the valve to prevent clogging and ensure proper operation.

Control Valve Applications

Control valves are widely used in various water coil applications:

- Chilled Water Coils:Control valves regulate the flow of chilled water to maintain desired temperatures.

- Heating Water Coils:Control valves regulate the flow of hot water to provide heating.

- Condenser Water Coils:Control valves regulate the flow of condenser water to optimize cooling efficiency.

FAQ Compilation

What are the common types of control valves used for water coils?

Globe valves, butterfly valves, and ball valves are widely used in water coil systems.

How do I size a control valve for a water coil?

Consider factors such as flow rate, pressure drop, and valve capacity to ensure proper sizing.

What are the different types of actuators used for control valves in water coils?

Electric, pneumatic, and hydraulic actuators are commonly used, each with its advantages and disadvantages.